Technical parameters

| Model | ETA-PV520 |

|---|---|

| For Bag Length*a | 80-370mm |

| For Bag Width*a | 60-250mm |

| Max Width of Roll Film | 520mm |

| Control Panel Size | 7’’ Color Touch Screen |

| Packing Speed*b | 5-60 Bags/min |

| Contact Parts Material | 304 Stainless Steel |

| Air Consumption | 0.65Mpa 0.4m³/min |

| Control System | Siemens PLC |

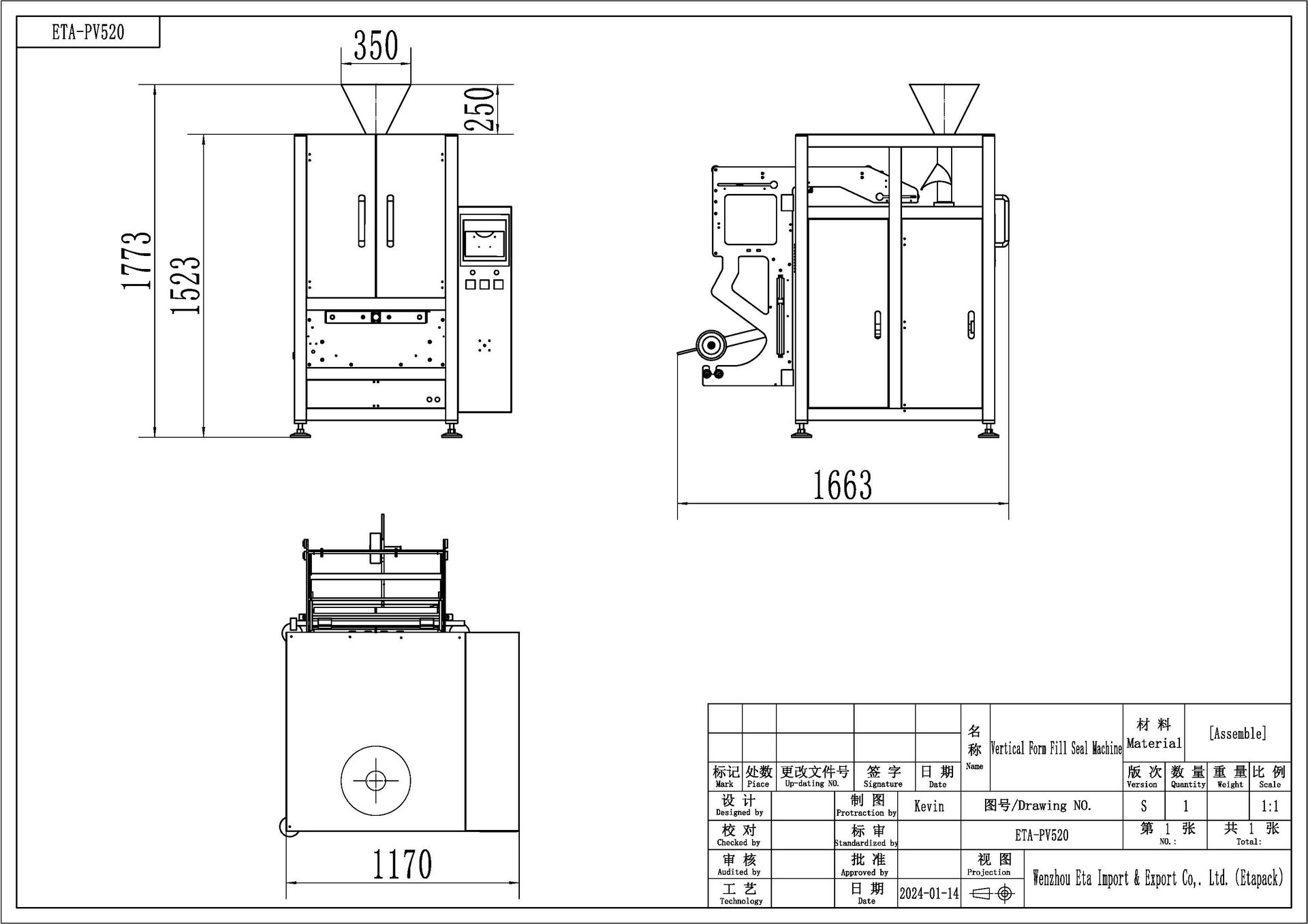

| Machine Size (L x W x H) | See Under Detail Drawings Or ask for CAD/PDF files. |

| Power Requirement | AC220V ±10% 50Hz(60Hz)3000W |

| Machine Weight | 800kg |

| Wooden Package Size (L x W x H) | 1500x1170x1500mm 850KGS |

*a: This machine forms bags by Roll Film, bag size is fixed by requirements. If you have to change bag width for a new product, you need to change film size and Bag Former together. The bag length is adjustable in the machine by setting.

*b: The actual speed is related with the bag size and packing weight.

Machine Fcunion

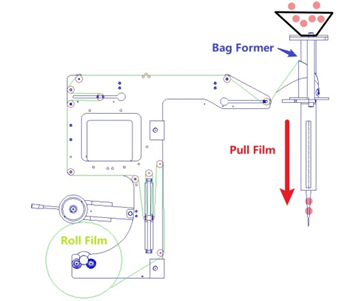

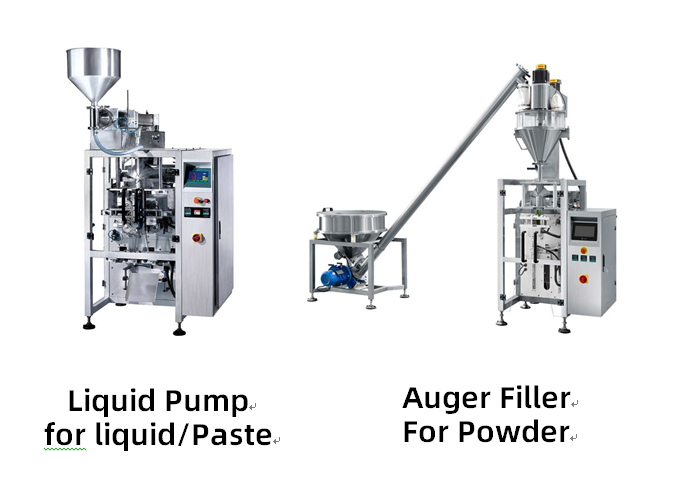

This machine can make bags from Roll Film and control outside product filling system to discharge product before it seal and output the bag.

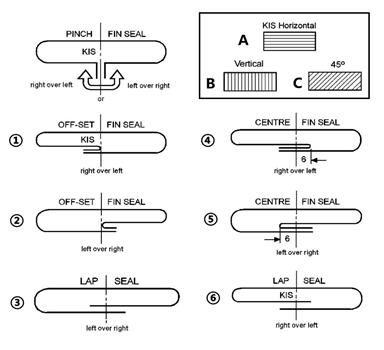

Step1: Machine pulls film through a Bag former to get the shape of the bags. Meanwhile, it will seal the backside of the bags (We also call it back seal, see back seal type ①-⑥)

Step2: Machine then will send out Ready signal to outside filling system. After outside filling system discharge the product and will feedback the signal to the vertical machine to make Horizontal seal (Which will make the end seal for the bags, the end seal pattern can do like photo A-C shows.)

Step3: The machine continues the cycles to produce.

Bag Types

Some Typical Option

□ Bag Former (Other width size for the bags, extra replacement.)

□ Nitrogen Adding Pipe (for product need to add nitrogen gas, note the machine only provide the device and function, you still need to prepare nitrogen gas yourself)

□ Gusset Device (to make gusset for bags, it will fold film on the sealing area)

□ Servo Sealing Device (changes the horizontal sealing bar moving by servomotor, will speed up the sealing speed.)

□ Bag Pusher Plate (will reduce the air inside bag before sealing)

□ Thermal Transfer Date Printer (TTO Printer, set date by setting, and special code on bags.)

□ Take Away Conveyor (take out finished bags from the under of the packing machine)

□ Rotary Table (collect bags from the output of the take away conveyor)

Machine Drawings

Typical Application

Frequently Asked Questions(FAQ)

Introduction of this section.