Premade Bag Packing Machine

ETA-PR8-300

ETA-PR8-300

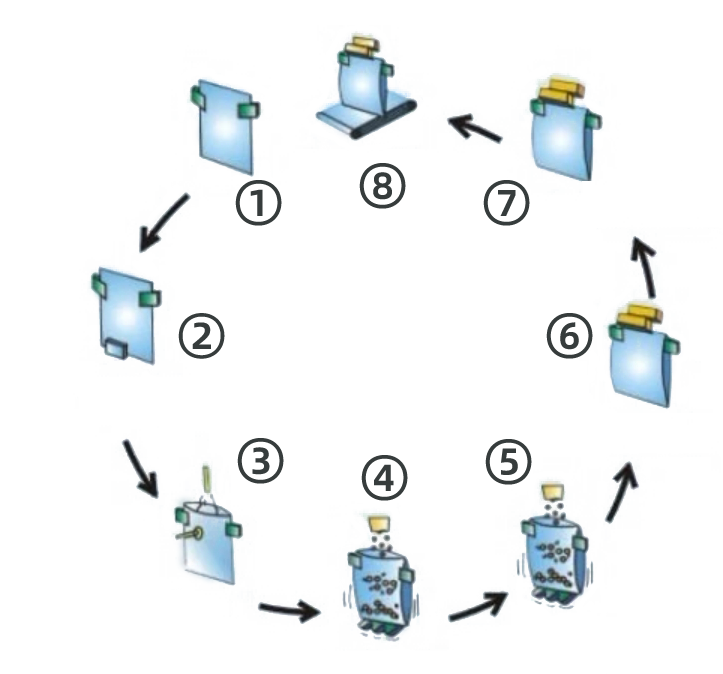

Premade Bag Packing Machine is a kind of machine to pick up empty premade bags, open bags and control outside filling device to fill product into bags, then seal and output the products.

- Replacement for Band Sealer or Manual Sealer

- Adjustable for different size bags within its range

- Speed 20-40 Bags/min

- Stable Sealing Quality for Large Quantity Production

More Details

Sepcifcations

Machine Fuction (Station)

Station1: Pick up empty premade bags.

Station2: Date Coding*[3] + (Option) Open Zip Locker

Station3: Open top and bottom of the bag.*[4]

Station4: First Material-filling Station*[5]

Station5: Second Material-filling Station and Bottom Vibration as required.

Station6: (Option) Bag Pusher to reduce inside air or (Option) Nitrogen Adding for product keeping. And The First Hot Seal Station for pre-seal.

Station7: Second Hot Seal Station.

Station8: Cold Embossing Stations. And Output Conveyor.

Bag Style it Can Pack

- 3/4 Side Seal Bag

- Doypack(Stand Up Bags)

- (Some) Spout Bags with cap on the corner

- Other special bags please confirm with our sales.

Features

- SIEMENS Touch Screen and PLC Controller.

- Main Motor Driven by Frequency Converter, speed controllable.

- Uses branded air cylinders and drivers.

- 304# stainless steel construction.

- Suitable for a wide range of bags and various product types.

- Self-diagnosis function: Prevents filling and sealing when it detects that the bag is not open or not fully opened.

- Automatically triggers an alarm if there are issues with the air pressure or heating elements.

- When a malfunction occurs, the machine will automatically shut down to protect the equipment.

- The pouch width can be directly adjusted through the touch screen.

- Zipper opening device driven by a servo motor.

- Achieve perfect sealing to enhance product presentation and improve overall quality.

- Comply with CE, GMP and HACCP standards.

- Bag material: Composite film, monolayer PE films, PP, etc.

Some Typical Option

□ Simple Bag Stocker (suitable for flat bags)

□ Bag Lifting Stocker (suitable for soft and big size flat bags)

□ Servo Zipper Opener (if you need to open zipper bags)

□ Inkjet Printer / Thermal Transfer Printer /Laser Printer

□ Nitrogen Adding Pipe (we don’t supply nitrogen gas)

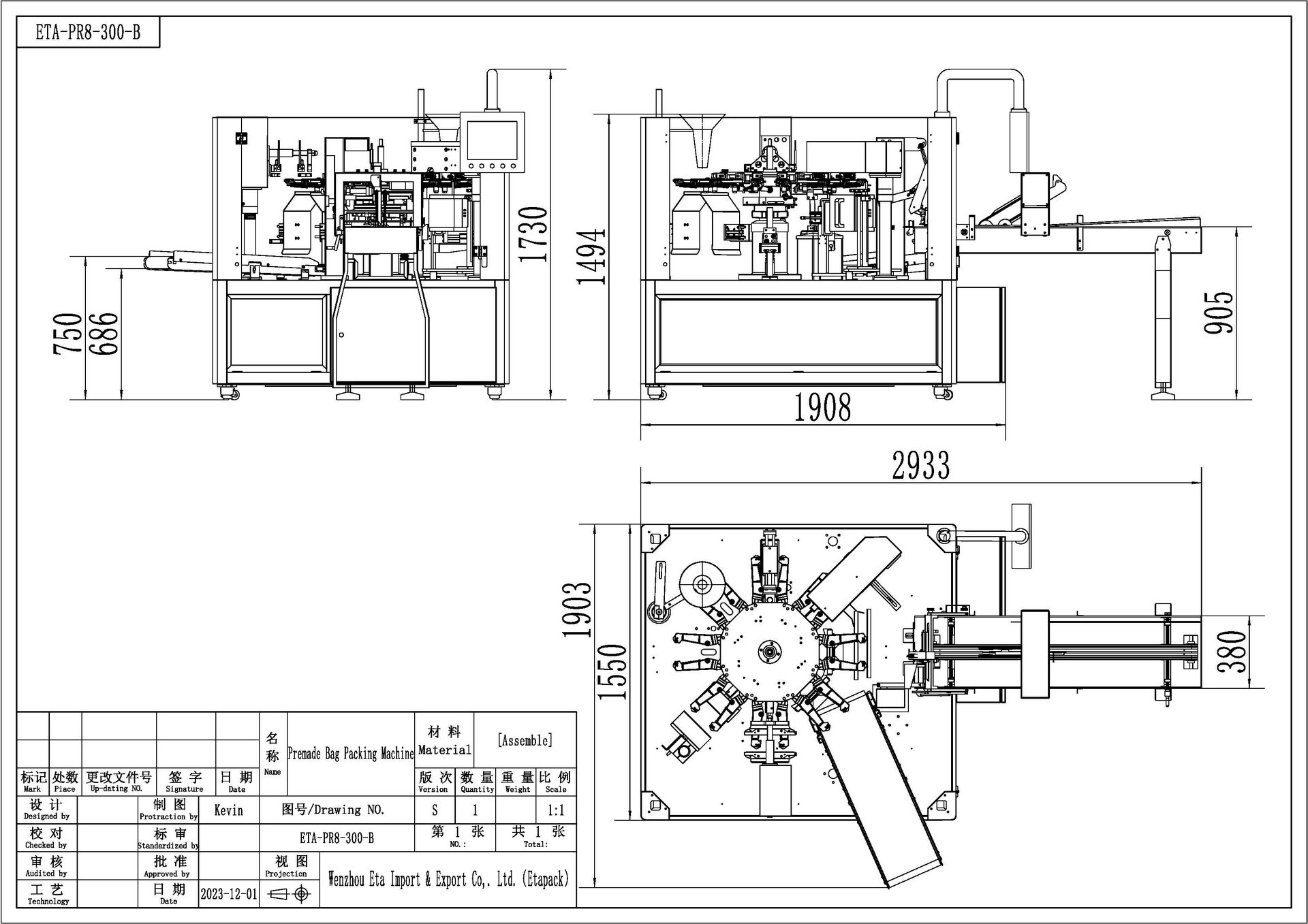

Machine Layout

Machine size as photo shows. This is only the packing machine layout. If you need PDF/CAD files, please contact with us for the newest files.

Please note, if you need to make the system to work, you may also need product weighing and dosing system. Please contact with our experts, and we will learn more about your business and your physical work area, then we will provide you whole packing layout design for FREE.

Notes:

[1]: The actual packing speed is related with the packing product properties and packing weight. If the packing product is easier to be weighed, and easier to fill into bags, the speed will be faster. Also the bag type and filling quantity will influence the packing speed.

[2]: The air consumption is related with the function chosen. If the machine equipped many extra functions that need extra compressed air, then it will cost more air. If there is also other machines need air supply, factory can consider building a compress air center to supply the compressed air.

[3]: Standard Coding Method is by Hot Stamping Machine, we have option for inkjet and thermal transfer printing.

[4]: Machine will try to detect if the bag is correctly opened between Station3 and Station4, if the bag is well opened, then will fill and seal this bag in next remain stations.

[5]: Product will be controlled to discharge into bag by machine on this station, like liquid, powder, granule or manually put product into…

Advanced Quote

Notes: You will get a more specific quotation by submitting the under form. This is based on your knowing about our products description above. Or Contact Us, and we will assign our sales to contact you. Thank you.

Related Products

ETA-PR6-350

Description of this modle machine.